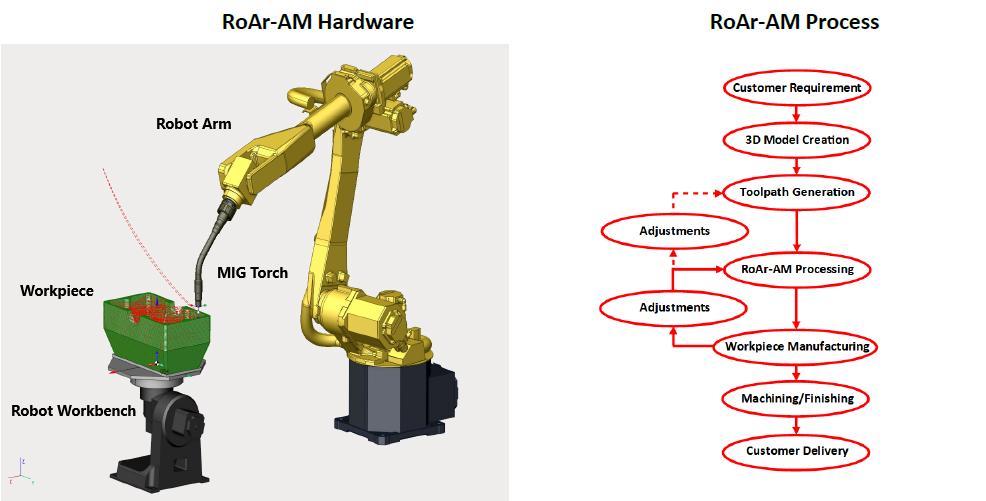

Robotic Arc-weld Additive Manufacturing (RoAr-AM) is an in-house developed 3D printing technique using a robotically controlled arc-welding process to form parts directly from a computer 3D model file.

The technique fills a gap between casting, which is suited to mass production, and current 3D metal printing techniques such as SLM (selective laser melting) which is suited to small, high-detailed parts and is currently suited to aerospace and medical applications.

RoAr-AM has a high deposition rate but lower quality surface finish and larger minimum feature size than SLM printed parts. The technique produces a near net-shape part, meaning the tolerance of non-machined surfaces is similar to most casting processes.

Materials: Aluminium, Mild Steel, 316L Stainless Steel, high-tensile steel and 35HRC hard steel

Minimum feature size: 3mm

In July 2015 we produced our first 3D printed parts using an in-house developed 3 Axis CNC bed.

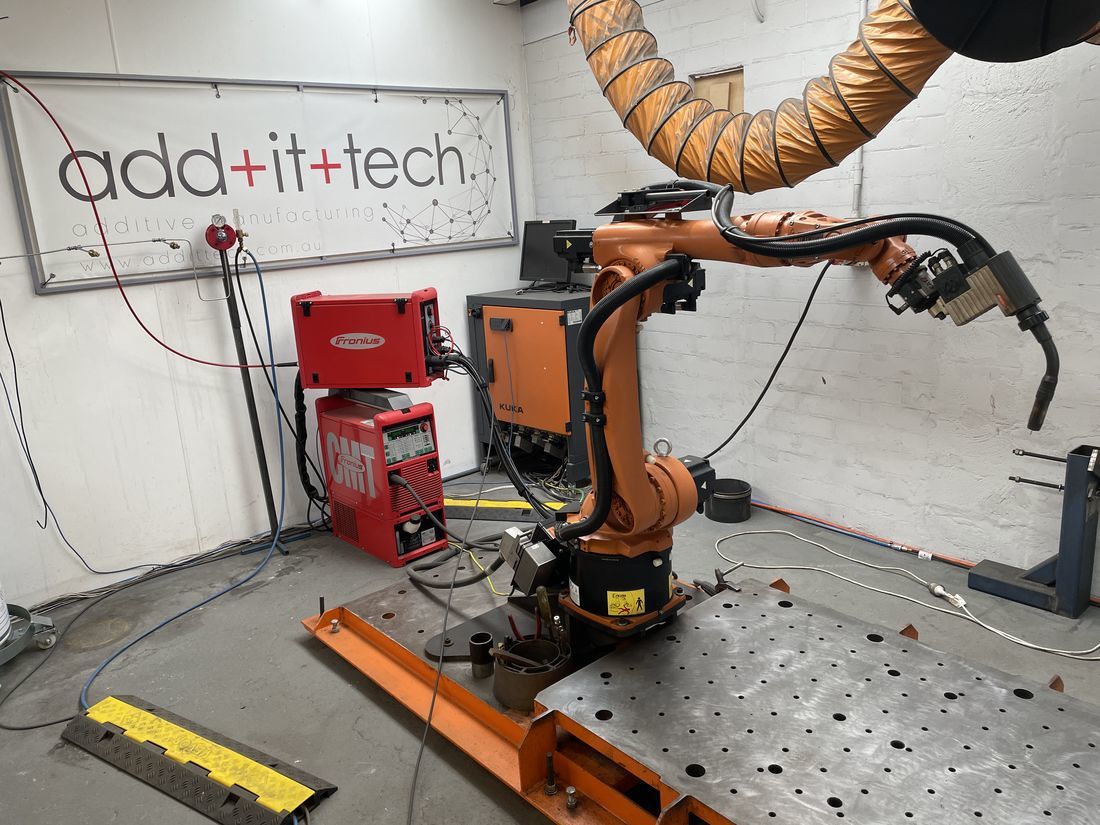

Currently we are refining our 6 axis robotic arc-welding system and software to generate parts in 3D directly from a 3D model.

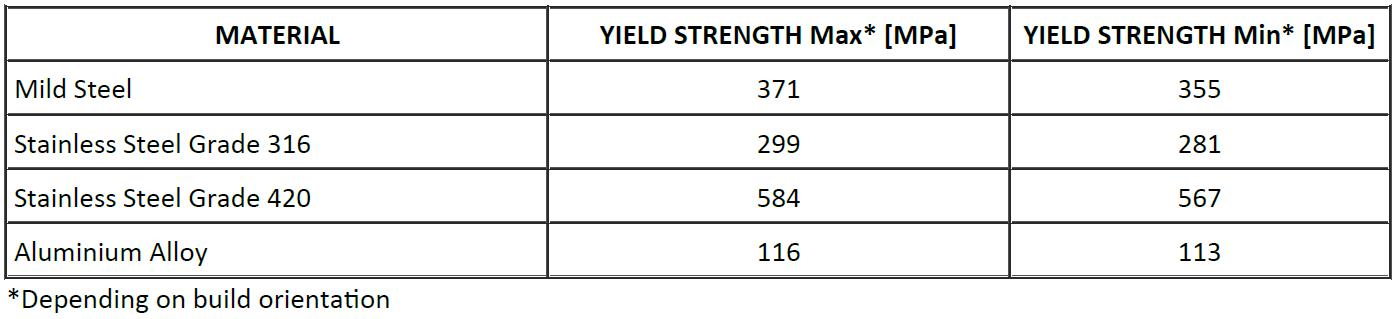

We have conducted a metallurgic and mechanical properties testing evaluated by a NATA approved testing laboratory.

|  |

| add+it+tech RoAr-AM System | Tensile test samples post testing |

One benefit of WAAM technology is integrating traditional and advanced manufacturing processes.

Wanting to engineer a ship propeller of approximately 500mm diameter, we divided the project into two phases:

1 - Traditional process to prepare the propeller hub (machining on a lathe)

2 - Advanced process to shape the blades around the hub (3D printing with our RoAr-AM system)

In this case, the method to subdivide the job into two different stages further help customers to save time and money.

Printing time 25hr

Those bearing housings present a large surface area to volume ratio, making them unrealizable to machine from solid billets.

Similarly, the part might be ready in a month and at a high cost using a metal casting process.

With our RoAr-AM system, we can manufacture the workpiece within two days.

Printing time for the 18Kg bearing housing 12hr

Printing time for the 5Kg bearing housing 4hr