- Aluminium

- Cobalt-Chrome

- Titanium

- Steel

- Superalloys

- AlSi10Mg

- HastelloyX

- Haynes230

- Stainless Steel 316L

- Super-Duplex

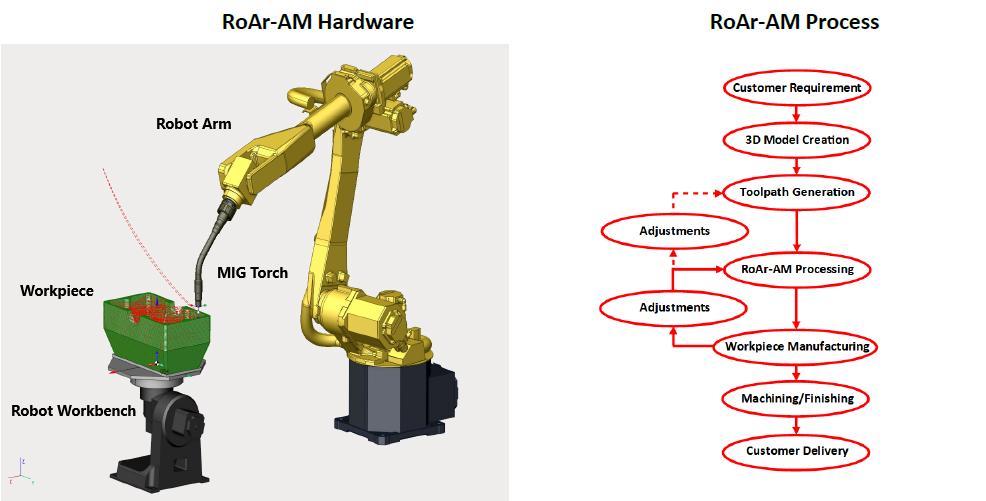

Robotic Arc-weld Additive Manufacturing (RoAr-AM) is an in-house developed 3D printing technique using a robotically controlled arc-welding process to form parts directly from a computer 3D model file.

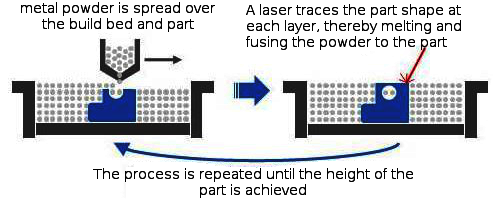

The technique fills a gap between casting, which is suited to mass production, and current 3D metal printing techniques such as SLM (selective laser melting) which is suited to small, high-detailed parts and is currently suited to aerospace and medical applications.

(To discover more about our AM capability click here)

Selective Laser Melting (SLM) is a process whereby metal powder is laser sintered in layers, as shown in this graphic:

SLM printed metal parts can be highly detailed and accurate and the materials that are available include the common steels and aluminium. Additionally, SLM printing offers exotic materials including:

SLM printed parts can be post-treated in a Hot Isostatic Press (HIP), to close up any micro-porosities, giving mechanical properties very similar to the cast metal and allowing parts to be used for production.

SLM machines are highly specialised devices designed to provide an inert environment during the build, parts are generally very accurate and detailed, however the build size is often limited to smaller parts. In some instances, other technologies may be better suited to achieve the desired result, such as our in-house RoAr-AM process for larger and less detailed parts, or casting directly from a 3D printed plastic part.

Don't hesitate to contact us at add+it+tech to discuss the many possible options.

|  |

| SLM machine from SLM Solutions GmbH (Germany) | Powder bed with laser scribing the profile for the layer being constructed |

Some examples of SLM printed parts: